|

GIANT ROBOT ANT - SUSPENSION SYSTEMS

|

||

|

SUPERB DESIGN - In the main you can't beat nature. Sclerotin is a component of insect exoskeletons, the structural material of their body. It is formed by cross-linking protein molecules, a biochemical process called sclerotization. Technically it amounts to a form of tanning. The resulting material adds physical stiffness to the toughness of an insect's chitinous (cellulose like) body parts. It is particularly prominent in the thicker, armoured parts of insect and arachnid integument, such as in the biting mouthparts and sclerites of scorpions and beetles. Combined with calcium carbonate, as in the shells of crustaceans and molluscs, chitin produces a stronger composite that is harder and stiffer than pure chitin and is tougher and less brittle than pure calcium carbonate. These bio-materials are the building blocks of life.

CHRISTMAS ROBOT ANT PROJECT - RUNNING SMOOTHLY

The suspension system of the Christmas Robot consists of three part legs with: traction pads (rubber & spikes), springs, shock absorbers and linkages - that connects the chassis of this robot (a vehicle) to its feet and allows greater tolerance to surface irregularities between the feet and the ground on which the robot stands.

Suspension systems serve a dual purpose - contributing to the vehicle's terrain handling capability, including acceleration, cornering and braking. The aim is to keep the vehicle and any cargo safe, by reasonably isolating the motors and control electronics from bumps and vibrations.

These goals are generally at odds, so the tuning of any suspension involves finding the right compromise. It is important for the suspension to keep the feet in contact with the land surface as much as possible during a walking (or running) cycle, because all the ground forces acting on the vehicle do so through the contact patches of the feet. When speaking of suspension, we normally think of a car - and for this article there will be many analogous examples.

Suspension systems can be broadly classified into two subgroups:

1. Dependent, and

2. Independent.

These terms generally refer to the ability of the opposite end of an axle to move independently of each other, but in robots there may be no suspension system at all between four or more wheels. Our suspension system is fully independent.

Suspension attachments must match the frame design in geometry, strength and rigidity. In this case the rotational frequency is 900rpm, or 15 cycles per second. Both sprung and unsprung mass is therefore critical as is the attachment points.

We

will now take a look at all the components of the suspension of this giant

animatronic ant - and decide what components to use as we consider the

technology that gives us movement over land.

SPRINGS - Here we see a tension coil spring and a compression coil spring.

LEAF SPRINGS

BIOLOGICAL

INTERFACE

- These are cheetah blades, in effect, high performance leaf springs. They

worked so well that paralympian Oscar Pistorius got into a dispute with

the IAAF. The London (August) 2012 Paralympics we're

focusing on the most talked-about equipment used at the games - carbon-fibre prosthetic blades inspired by the hind legs of a cheetah.

NIKE - South African double-amputee sprinter Pistorius previously used regular track spikes

with his blades and had to glue or tape the plates on in a process that took a couple of hours before each race and meant they were never quite the same twice.

COIL SPRINGS

A coil spring, also known as a helical spring, is a mechanical device, which is

used to store energy and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. They are made of an elastic material

(spring steel) formed into the shape of a helix which returns to its natural length when unloaded.

WEIGHT TRANSFER

Unsprung weight transfer is calculated based on the weight of the robot's components that are not supported by springs. This includes foot pads, lower legs, dampers and other components.

Sprung weight transfer is the weight transferred by only the weight of the robot resting on the springs, not the total vehicle weight.

SPRING

TRAVEL

Bottoming or lifting a leg can cause serious control problems or directly cause damage. "Bottoming" can be caused by the suspension and leg, etc. running out of space to move or the underside of the body or other components of the robot hitting the ground.

BUMP STOP

Without bump-stops, a fast robot that "bottoms out" will experience a very hard shock when the suspension contacts the bottom of the frame or body, which is transferred to the workings and every connector and weld on the steel frame. In the case of cars, factory vehicles often come with plain rubber "nubs" to absorb the worst of the forces, and insulate the shock. When a desert race vehicle, that routinely absorbs far higher impact forces, may be provided with pneumatic or hydro-pneumatic bump-stops. We'll be using simple rubber blocks during development.

DAMPING

BIOLOGICAL INTERFACE - In this spectacular photograph of Amy Purdy by Paolo Kudacki, we see the snowboarding paralympic medalist and her prosthetic lower legs and feet. Here is a fine example of bio-engineering where suspension is put to good use to give Amy a chance to show her skills on the slopes. Metal is allied to bone to achieve this performance.

A cheetah's frame is also bone based. The flexibility and speed of the cheetah is astonishing, given that their frame or skeleton is made from calcium. Bone is one of the strongest materials found in nature. Ounce for ounce bone is stronger than steel - a bar of steel of comparable size would weigh four to five times as much but is only twice as strong. In tensile strength bone is rather like cast iron, although around 1/3 of the weight, in bending stress it behaves like steel. But it is the design of a bone that is important for strength. For example, many bird bones are hollow, with struts or trusses (cross walls) that crisscross for structural strength.

FLEXIBILITY

Due to weight and cost considerations, structures are not made more rigid than necessary. Some vehicles exhibit detrimental vibrations involving the flexing of structural parts, such as when accelerating while turning sharply. Flexibility of structures such as frames and suspension links can also contribute to springing, especially to damping out high frequency vibrations.

The head and tail of the ant may contribute to overall flexibility, as may rubber mounted motors and transmission - though that is not a priority for the development prototype.

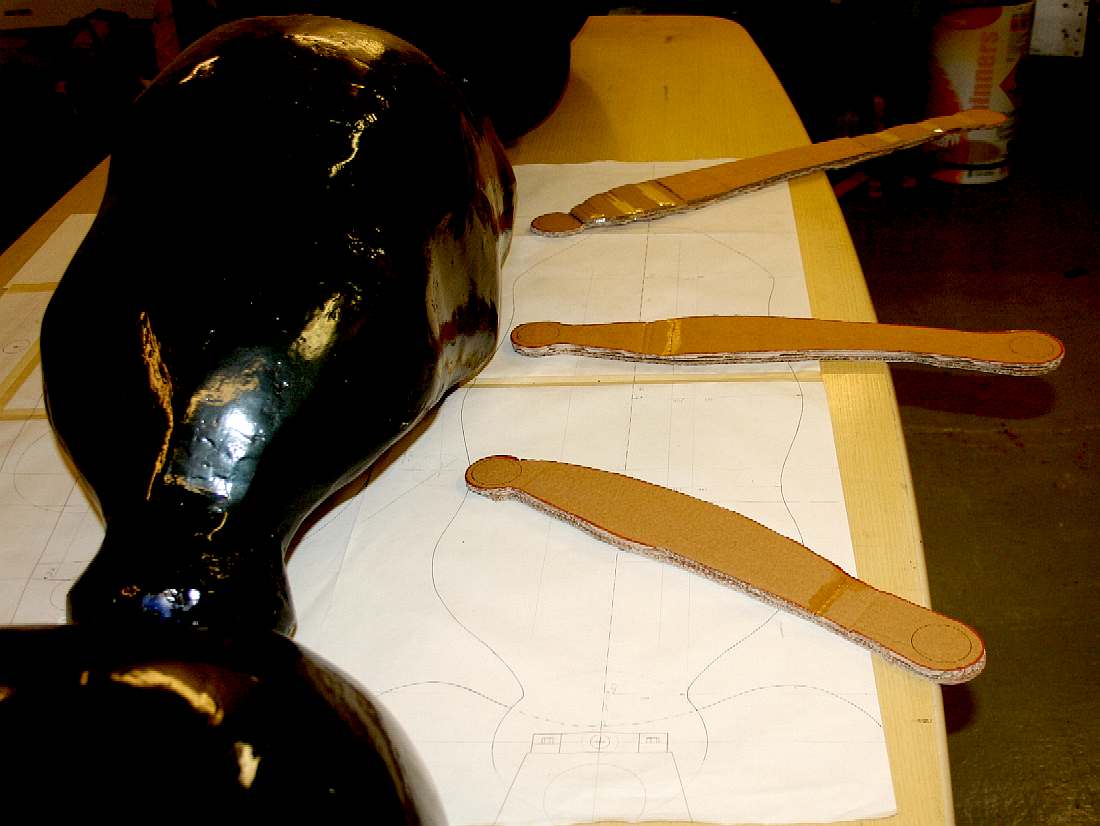

LEG MASS v COST - Aluminium legs in 28.5mm tubing is likely to be around £35 + delivery, whereas, titanium in 25 and 19mm tubing will run to £138 + delivery. The price for carbon fibre will be significantly higher because of the moulds, but we need leg patterns anyway for film special effects. Please note that this photograph is copyright © Jameson Hunter Ltd 2015. You will need permission from Jameson Hunter to be able to reproduce it.

GEOMETRY - Careful design of the leg is important if we are to avoid another actuator for the lower leg. We are thinking about a two-stage spring loaded system at the moment - with shock absorption. Amputee athletes use a similar system for high speed track events. Please note that this photograph and the subject drawing are copyright © Jameson Hunter Ltd 2015. You will need permission from Jameson Hunter to be able to reproduce it.

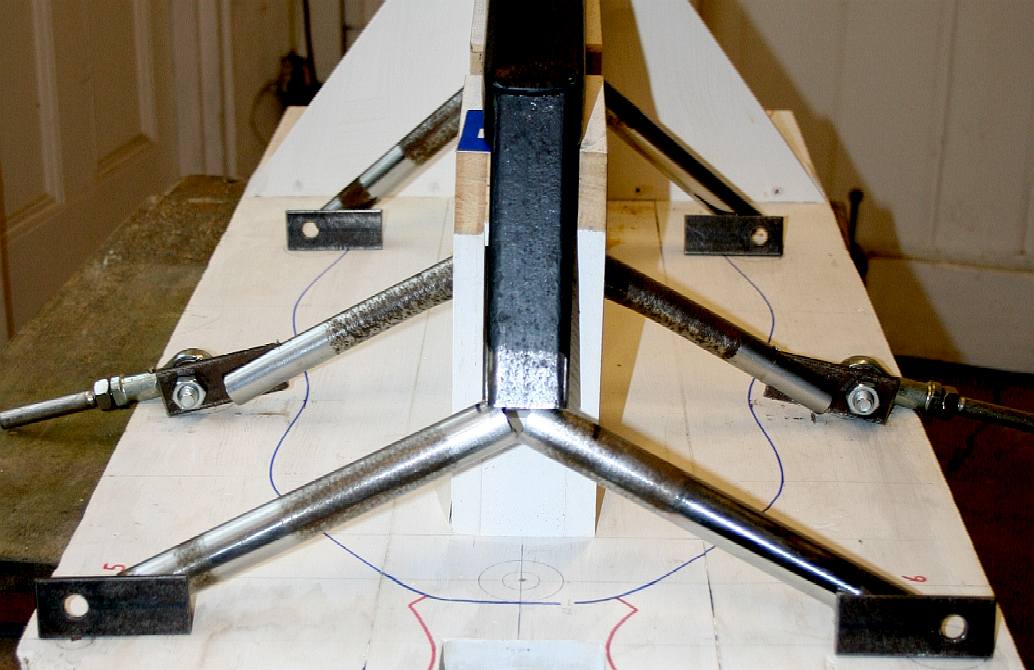

AXLE MOCK UP - December 27th - More progress. Working in steel is time consuming when prototyping demands constant fine adjustments. Once the angles are all worked out it is not so bad - working them out means many cups of tea and coffee - to gather ones thoughts. Please note that this frame is Design Copyright and that this photograph is Copyright © Jameson Hunter Ltd 20 December 2015. All rights reserved. You will need permission from Jameson Hunter to be able to reproduce it.

LEFT - Movie idea, lurking beneath the Antarctic ice is a discovery that scientists will die for. This story is now the subject of a low budget trailer to be produced mostly in the UK. The promoters are looking for backers. The UK will contribute 20% toward production costs. Roughly 60% of a low budget film may be pre-sold as distribution rights, leaving 20% finance to source. The deal is that investors recover 120% on their project stake within 12 months of shooting, with an income stream thereafter from networks and merchandising. Producers and directors please take note that there is a significant audience for well made movies of this genre. Look at what happened when they remade Godzilla.

A Sectasaur™ (thawed) - now on permanent display at Herstmonceux Museum, in Sussex, England.

ANTICS - ARDUINO - ARMOUR - ARTWORK - BIPEDAL HUMANOIDS - BLACK BOX - CHAT GPT - ELECTRONICS - ENERGY - FRAME - FORMICARIUM HEAD - INVISIBILITY - JAWS - KITS - LEGS - MECHANICS - MOTORS - MOVIE - RASPBERRY Pi - R/C DRONE - SENTRY - SOFTWARE SIM CARDS - SMARTPOHNES - SOUND PROOFING - SPACE ROVERS - SPEED - STEM - SUSPENSION - TAIL - WEAPONS - WARGAMING

|

||

|

This website is Copyright © 2023. The design of the Robot Ant on this page is design copyright © December 15 2015, all rights reserved - Jameson Hunter Ltd. IMPORTANT NOTE: Under no circumstances may our products, or those of Jameson Hunter Ltd, be used by any military or law enforcement organization, for any warlike, combat, or peacekeeping crowd control purposes. Anyone purchasing one of these units will be required to sign a binding undertaking (Deed) to that effect. Any unit found to have been purchased by proxy, will be confiscated, along with civil remedy in respect of breach of contract, that all parties in the chain will be vicariously liable for - to include damages for vehicles developed from our designs without our consent - and possible fraud issue from the deception. In addition to copyright theft, the law of passing-off applies.

|