|

GIANT ROBOTIC ANT - JAWS, TEETH & BITE

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FABULOUS - Stupendous jaw length and nice sharp teeth as diamond sharp pyramids. The hairs on the jaws are sensors that help this aggressive hunter to be more effective. She may be an effective hunter, but she is also a caring mother.

Almost all animals have teeth and jaws to be able to eat food, chew it up into small pieces and digest it. In humans we no longer use our teeth to capture and kill prey because we are now civilised, but in the wild an animal (lions, crocodiles, sharks) that does not (yet) have the ability to reason, must be equipped through millions of years of evolution to survive autonomously. The design of the jaws (or mandibles) of an insect are therefore crucial if they are to exploit their ecological niche.

In this article we'll be looking at the design of a set of jaws some 500mm (20") long. We'll also be comparing the jaws of our robot ant to those of other ant species on this page, where some of those evolved are stunning creations, that nature produces in abundance - nature is like millions of teams of design engineers all over the world constantly looking to improve their product.

This is not limited to planet earth of course. Alien life is a statistical certainty. We would though have to be extremely lucky to meet another advanced life-form, given the millions of years we have taken to evolve - and taking into account that we will more than likely be extinct sooner than we might have been, if we don't stop climate change. Robots might then play a more important role in preserving what we are now, for future advanced life-forms to learn about us. For this reason, our next robot research project may be a lifelike humanoid.

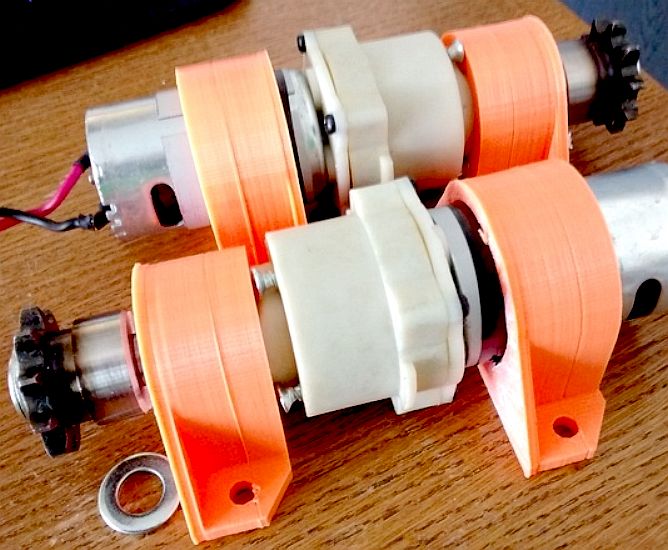

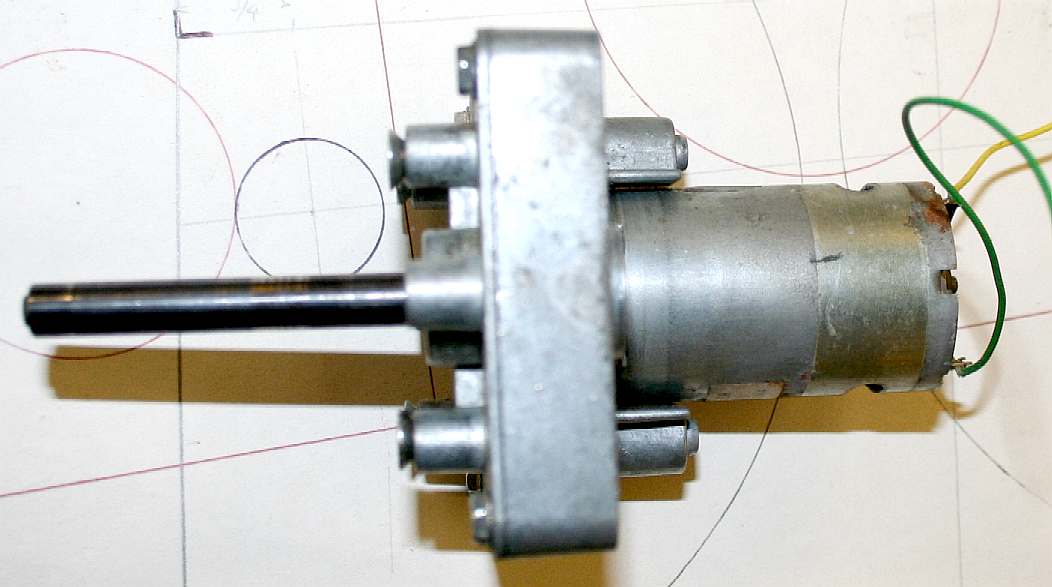

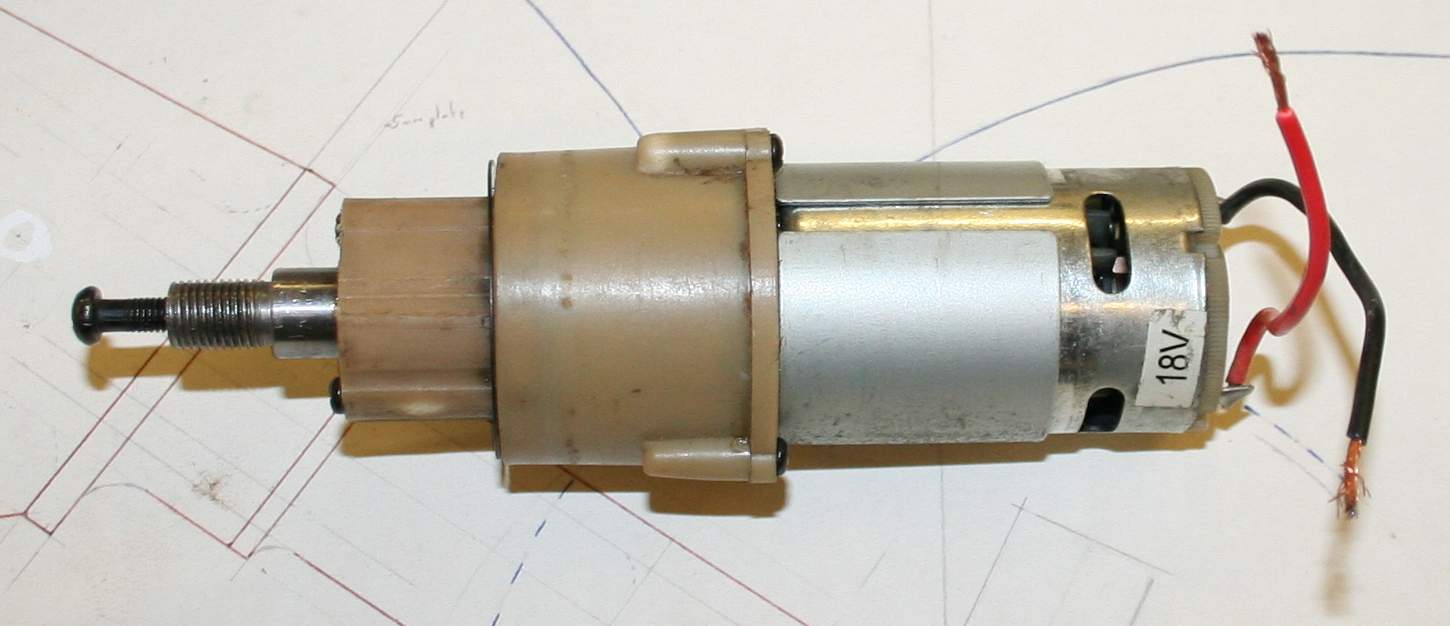

BARGAIN ACTUATOR - It involves a degree of sourcing and engineering, but hand drills convert nicely to make some high output servos. Cordless drill motors are great to drive larger robots around. The planetary gearbox gives lots of torque, but the limiter will need to be locked using a hack - or slippage will occur.

OPEN WIDE - You can see from the CAD plot above that the jaws open to 19" (490mm) from a 10" (250mm) input lever - almost a 50% mechanical disadvantage. In other words we've had to revise the ratios a little. We cannot make 60 pounds (27kg) of closing force at the tips without introducing more reduction gearing. Inefficient though it may be, our bargain servo will drive a 14mm x 2mm screw thread into threaded swivel blocks on either inboard end of the jaws, via a 3:1 reduction, multiplying our 40 lbs of force x 3 (minus losses) to give around 120lbs (54kg) of crushing strength. Some of you may have noticed that the head articulation is exactly the same 3 axis arrangement as a human arm - from the shoulder to the elbow, though why all the fascination with humanoids when humans cannot perform anywhere near as well as other animals. Please note that this frame is Design Copyright and that this photograph is Copyright © Jameson Hunter Ltd 20 December 2015. All rights reserved. You will need permission from Jameson Hunter to be able to reproduce it.

HEAD SERVOS - By comparison to the heavy duty RC servos used in most robot kits, the above units provide some serious grunt. They will take 12-24 volts without harming the motors - rpm is a product of voltage, so speed rises with voltage. [LEFT] The motor is a Mabuchi 540 frame driving through a reduction gearbox with steel gears. Two of these will provide head left (shake) and right and up and down (nod) [RIGHT] This is a similar motor from a battery hand drill. The epicyclic gearbox has been hacked, removing the clutching spring and ball bearings that are used to dial in variable torque for driving screws, etc. You can lock the drive by securing the steel outer gear casing to the plastic drill casing. We've inserted a liner that is a tight interference fit. When taking these units apart, be sure to do so in a large bowl or other contained area, or you will lose some of the ball bearings from the front thrust bearing. Clean and re-lubricate on re-assembly.

EPICYCLIC GEARS - Planetary gear trains provide high power density in comparison to standard parallel axis gear trains. The load in a planetary gear train is shared among multiple planets, greatly increasing torque capability, making the gearbox lighter. The more planets in the system, the greater the load ability and the higher the torque density, but also the higher the energy losses - in this case around 15% to be added to the 35% motor losses - and that is why servo based robots are not as efficient as they might be. A move to dc brushless motors for RC servos would be a giant leap forward. The motors shown here are inefficient brushed units - for the sake of economy.

Efficiency losses in a planetary gear train is in the range of 3-6% per stage dependent on proper configuration, compared to a chain drive that loses about 2-3% per stage (98% efficient). But this type of gearbox is compact, with reasonably low mechanical losses - provided that such a unit is well lubricated. We are great fans of proper lubrication. Go with helical gears if you want a gearbox to run as smoothly and quietly as possible, but beware the additional losses. Choose spur gears when you need to maximize the gearbox's torque density or working life under higher loads. Needle roller bearings improve efficient. Hand drill units don't have ball or needle bearings as a rule.

HEAD & JAWS - The head and jaw parts placed in roughly the right position. The neck bearings on the right need to be joined (welded) and mounts made for all three of the servos. The jaws (shown here as a cardboard pattern) need to be made in steel and composites. At the moment we're using 18mm spherical rod ends for the jaw main bearings to cope with 120 lbs of closing power and the ability to lift a person into the air. There are a lot of levers and control rod couplings to make - and some more mountings that sit on top of the head frame, for the antenna. The jaw motor drives a threaded bar that opens and closes the mandibles, further reducing the drive ratio, and so increasing closing torque. Please note that this frame is Design Copyright and that this photograph is Copyright © Jameson Hunter Ltd 2 January 2016. All rights reserved. You will need permission from Jameson Hunter to be able to reproduce it.

CHRISTMAS PROJECT - ROBOTIC CHALLENGE

The jaws could be made of GRP and leave it at that, but for the fact that this animatronic will also be used for stunt work. For that reason we need a performance pair of jaws. Jaws that can at least slice through plastic and cardboard (and possibly simulated meat) without harming any actors.

The problem is that jaws sharp and strong enough to cut soft materials will also main human actors unless precautions are taken. We are thinking that the sharp jaws will have protective covers fitted when filming actors. The teeth in "Bruce", the animatronic shark in "Jaws" the movie, were soft and flexible - because they were not intended to perform.

The previous frame for the head was a complex design made from sheet metal to form an incredibly strong box with hinges at the front for the jaws and a special dual-axis neck joint. This design was expensive and complex, when the design brief here is simplicity and affordability. For that reason we are replacing the monocoque design with a simple "T" frame made from two lengths of 50mm and 40mm steel box section (RHS). The "T" at the mouth end of the robot, carries a hinge at either end, into which the jaw sections are fitted. It will take more than a couple of (model radio control) jumbo servos to operate the jaws. We are thinking epicyclic gearbox and brushless motor to generate around 92ft/lbs of torque (125Nm).

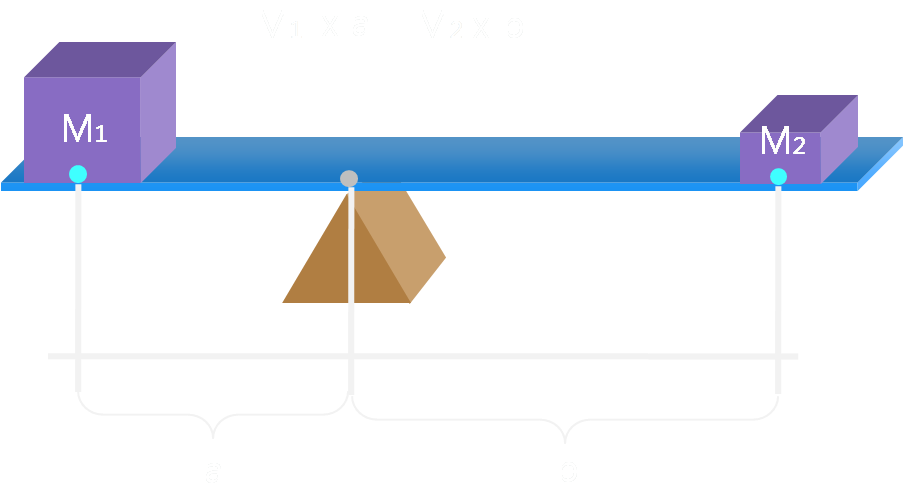

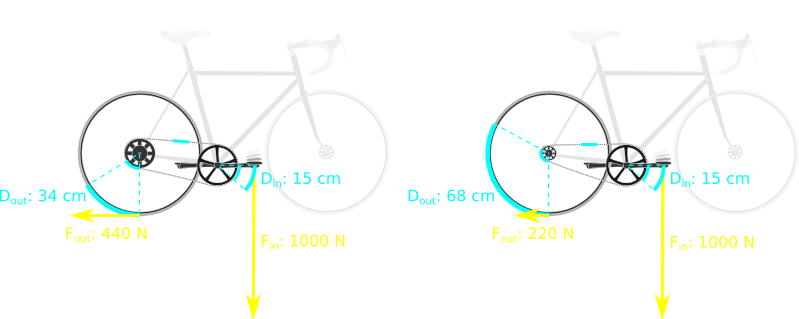

LEVERAGE - Think of when you first sat on a see-saw, great fun wasn't it? If you were heavier the other swinger went up in the air. if they were heavier, you shot up. That was with the pivot point of the see-saw in the middle. If we move the pivot point, then if you were M1 in the picture above (and heavier) you could move M2 a greater distance using the mechanical advantage (a) compared to the distance (b). Levers can work either way as in the bicycle below.

LEVERAGE - [LEFT] the gear is low (1st) providing good acceleration and traction up hills. [RIGHT] the gear is high (5th) providing a higher speed, having accelerated through the gears.

One foot-pound force = 1.35581794833 newton-meters. The SI derived unit for energy (work done) is the joule. 1 joule is equal to 1 newton meter, or 0.737562149277 foot-pounds of force. The force applied at the cutting tips of our robot jaws with a motor/gearbox providing 92ft/lbs of torque, will be 60 pounds (27kg). More than enough for our purposes, without resorting to hydraulics - though we could easily double the force by using 2 motors. To put this into perspective, many of the new 18 volt cordless hand drills generate 125Nm of torque - and that is why these units are popular with roboteers. You will only get this kind of grunt with the latest dc brushless units - hence, shop around for parts if going DIY.

LEVERAGE

A lever allows us to increase a force applied. The amount of increase is known as the Mechanical Advantage Ratio. A crowbar is a good example of a leverage tool used to amplify the force that a human can apply to open a packing crate. A crowbar is a simple tool consisting of one piece of steel. Other mechanical devices or machine systems may use many levers or cogs of different sizes (gears) to achieve what the engineer wants to do. The gearbox on a car is in effect a revolving lever system where the ratio can be changed by the operator in real time to speed up a vehicle, or climb steep hills.

UGLY MOTHER - Natural efficiency in design can appear ugly at first sight, but once appreciated, that super efficiency can be interpreted as beauty. The jaws of a bulldog ant are super fit for purpose. The unmodified original of this picture was taken by Alexander Wild, according to Lisa Patten of Quantum Leap in Rome. We are reviewing the work of high profile insect photographers, where capturing images of insects is important work for entomologists.

USEFUL FORCE CONVERSION TABLE

NEAT - Not all ants have huge jaws. These are much smaller than some on this page, but they are sharp. Note that one tooth (hardened end of the mandible) on the right is chipped. These are not combat or hunting jaws, they are more general tools for living.

DINO ANT - Dino ponera is one of the world's largest ants. We like the black colour scheme and all rounder design of its mandibles.

ARMY ANTS

These

ants are famous for the enormous jaws of their soldier caste. The name army ant (or legionary ant or marabunta) is applied to over 200 ant species, in different lineages, due to their aggressive predatory foraging groups, known as "raids", in which huge numbers of ants forage simultaneously over a certain area.

TUSKS - More like the tusks of an elephant than the jaws of an ant, but these handed barbs make a brilliant suture if you happen to cut yourself in the bush.

Most New World army ants belong to the subfamily Ecitoninae, which contains two tribes: Cheliomyrmecini and Ecitonini. The former contains only the genus Cheliomyrmex, whereas the latter contains four genera: Neivamyrmex, Nomamyrmex, Labidus, and Eciton. The largest genus is Neivamyrmex, which contains more than 120 species; the most predominant species is Eciton burchellii; its common name "army ant" is considered to be the archetype of the species. Old World army ants are divided between the Aenictini and Dorylini tribes. Aenictini contains more than 50 species of army ants in the single genus, Aenictus. However, the Dorylini contain the genus Dorylus, the most aggressive group of driver ants; 60 species are known.[citation needed]

SOCIAL FOLLOWING - SYMBIONTS

ARMY ANTS - All the mechanical features of other ants, but a huge set of mandibles.

DORYLUS

Such is the strength of the ant's jaws that, in East Africa, they are used as natural, emergency sutures. Various East African indigenous tribal peoples (e.g. Maasai moran), when suffering from a gash in the bush, will use the soldiers to stitch the wound by getting the ants to bite on both sides of the gash, then breaking off the body. This use of ants as makeshift surgical staples creates a seal that can hold for days at a time, and the procedure can be repeated, if necessary, allowing natural healing to commence.

DOOR SHUT - Snapped shut, this is what the jaws of a trap-jaw ant look like. A fabulous picture by Oscar Blanco using a Nikon D80, Nikkor 60mm micro, Raynox DCR-250, Nikon PB-5 bellows, 2x Teleconverter at around 9x magnification. The area of photo is about 2mm. Nice one Oscar.

THE GUARDIAN MAY 2015 - GREAT ESCAPE

Many modern ants Trap-jaw ants are known as fast biters, but researchers have proved that their astonishing leaps, propelled by 140mph muscle movements, are an escape tactic.

SOLDIER ANT - Who needs eyes when you have jaws like this? Incredible though it may seem, this is an ant that is so specialized that eyes are a hindrance to the defence function. Might that be because a head without eyes is considerably stronger.

To investigate, Larabee and colleagues placed the trap-jaw ant (Odontomachus brunneus) head-to-head against the pit-building antlion, one of its natural predators.

Larabee acknowledges that the experiment belongs to the scientific school of “doing silly things to animals to figure out what they’re doing”. But simple experiments such as these can give real insight into animal traits and why they evolved in the first place, he added.

TRAP DOOR - These are the jaws of the famous escape artist, wide open. Though large and powerful, these jaws act like a giant spring to propel the ant away from danger.

TRAP JAW ANT

FIRE

ANT - Small jaws and eyes, but a painful sting. Fire ant is the common name for several species of ants in the genus Solenopsis. They are, however, only a minority in the genus, which includes over 200 species of Solenopsis worldwide. Solenopsis are stinging ants and most of their common names reflect this, for example, ginger ants and tropical fire ants. Many species also are called red ants because of their light brown colour, though species of ants in many other genera are similarly named for similar reasons. Examples include Myrmica rubra and Pogonomyrmex

barbatus.

The mandibles of O. bauri are an exaggerated form of the sturdy and long mandibles found in many ant species. Additionally, the muscles found in the mandibles of O. bauri are found in other ants, although those found in O. bauri are large and look very similar to those found in cicadas.

ANT

EXPERT DUNN LAB - Daniela Magdalena Sorger, PhD says that she is fascinated by ants:

"I study their natural history, taxonomy, distribution, behavior, and life history traits. "My research focuses on trap-jaw ants in the genus Odontomachus that live in the United States and tropical places like Costa Rica, Borneo, and the Philippines. I mainly focus on elucidating their phylogeography and population genetics. I am also interested in broad-scale geographic patterns in functionally relevant and conspicuous ant traits, be they physiological (thermal tolerance), morphological (trap-jaws, spines), or behavioral (drumming). Ants are my life and I love to talk about them and explain my research, especially to non-scientists, as I regard communicating my work to the world around me as an essential part of being a scientist."

Emails: dmsorger@ncsu.edu dm.sorger@gmail.com http://robdunnlab.com/people/d-magdalena-sorger/ https://www.linkedin.com/in/daniela-magdalena-sorger-1a361879

There are other ants with killer jaws such as the Strumigenys, Mystrium, Myrmoteras and Anochetus to name a few other ants within the same family with the same features. One commonly accepted theory suggests that the trap-jaw actually evolved independently at least four different times in ants’ history. This is because with the use of DNA sequencing, the phylogenetic tree which found that those ants with trap-jaws were not nested neatly in one portion of the tree. Instead they were found scattered around the tree. Therefore, it did not evolve once leading to the hypothesis of a common ancestor. Instead it evolved multiple times and each time it evolved it used a different feature of the ant’s mouth to produce the trap jaw. For instance, O. bauri’s trap jaw is built from the mandible joint; however, Strumigenys trigger is built from it upper lip. This type of evolution would be deemed as convergent evolution and the trap jaw would be considered an analogy. This is because they are all similar features but involved independently rather than a common ancestor.

BULLET ANT - The pain caused by this insect's sting is purported to be greater than that of any other hymenopteran and is ranked as the most painful according to the Schmidt sting pain index, given a "4+" rating, above the tarantula hawk wasp and, according to some victims, equal to being shot, hence the name of the insect. It is described as causing: waves of burning, throbbing, all-consuming pain that continues unabated for up to 24 hours. The JCB like jaws remind us of an earth moving scoop.

TIGER BEETLE JAWS - The fastest insect on land also has a hefty pair of mandibles. This animal sucks in another insect, such as a fly, and extracts the fluids, expelling the solids such as the shell. The digestive system is thus also high performance, in not wasting energy breaking down solid matter. Rather, the mouth is a superb design, doing most of the preparation work for the stomach.

LEFT - Movie idea, lurking beneath the Antarctic ice is a discovery that scientists will die for. This story is now the subject of a low budget trailer to be produced mostly in the UK. The promoters are looking for backers. The UK will contribute 20% toward production costs. Roughly 60% of a low budget film may be pre-sold as distribution rights, leaving 20% finance to source. The deal is that investors recover 120% on their project stake within 12 months of shooting, with an income stream thereafter from networks and merchandising. Producers and directors please take note that there is a significant audience for well made movies of this genre. Look at what happened when they remade Godzilla.

ENGINEERING DESIGN - Ants are fabulous fighting machines. Biological engineering is less of a compromise than man-made machines. The only advantage that machines have have that we build is that we can use any material we want to seek to compensate for design and manufacturing limitations.

A Sectasaur™ (thawed) - now on permanent display at Herstmonceux Museum, in Sussex, England.

ANTICS - ARDUINO - ARMOUR - ARTWORK - BIPEDAL HUMANOIDS - BLACK BOX - CHAT GPT - ELECTRONICS - ENERGY - FRAME - FORMICARIUM HEAD - INVISIBILITY - JAWS - KITS - LEGS - MECHANICS - MOTORS - MOVIE - RASPBERRY Pi - R/C DRONE - SENTRY - SOFTWARE SIM CARDS - SMARTPOHNES - SOUND PROOFING - SPACE ROVERS - SPEED - STEM - SUSPENSION - TAIL - WEAPONS - WARGAMING

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

This website is Copyright © 2023

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||