|

FABULOUS

- Stupendous jaw length and nice sharp teeth. The hairs on the jaws are

sensors that help this aggressive hunter to be more effective.

There

are degrees of effectiveness of armour and bullet proofing, depending on

what you are trying to achieve. We are not looking to emulate military

grade combat proofing. We want a wider spectrum of cover against rock

throwing, knife attack, hits from wooden

bats, laser and tazer strikes. In among all of that it might be nice if we

could stop an arrow and rifle fire. It would be even nicer to survive a

grenade or other bomb blast. The emphasis being that it would be nice. It

would also be costly, raising the question: why would we want to go to all

that trouble? We don't. But once again, in the spirit of the insect that inspired

this project we would like the robot to be a tough little bugger - should

the worst come to the worst. Useful in wargaming - an end use much like

the robot

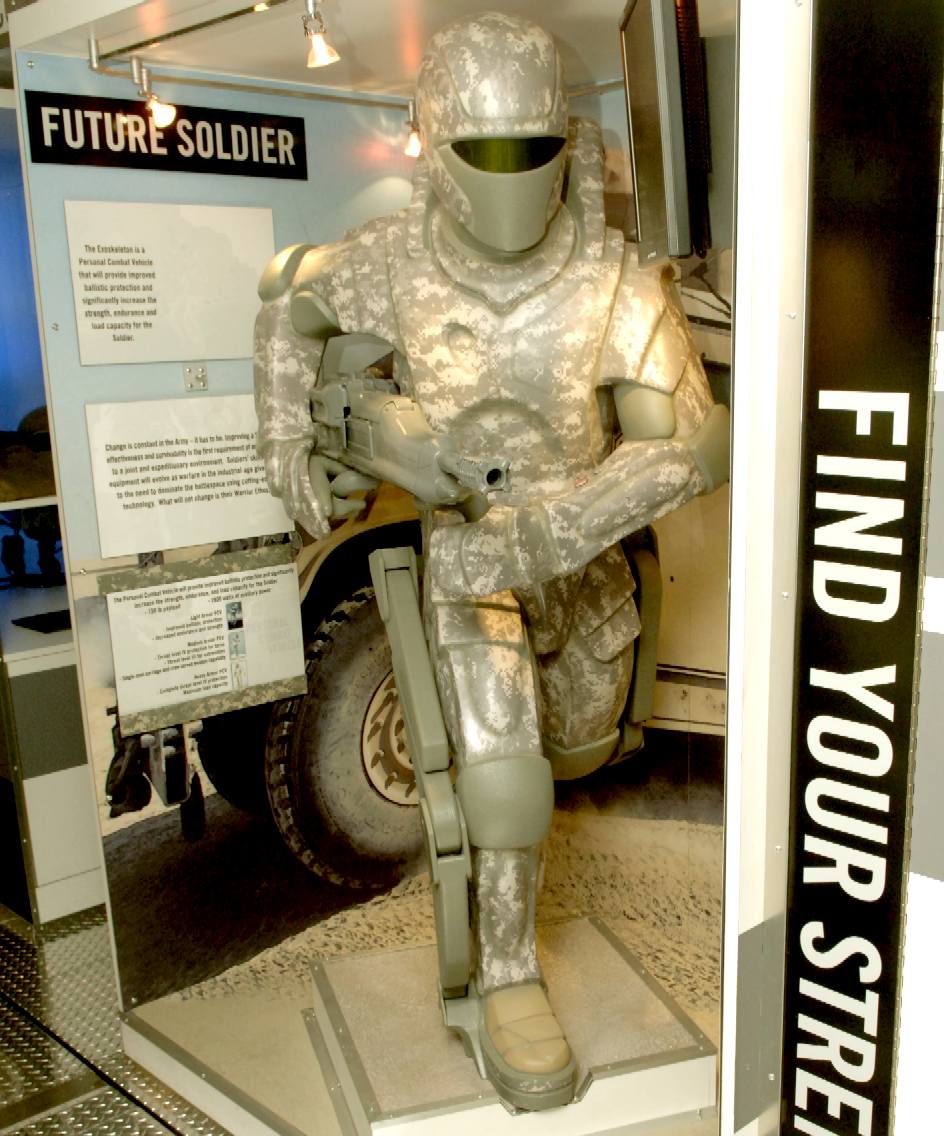

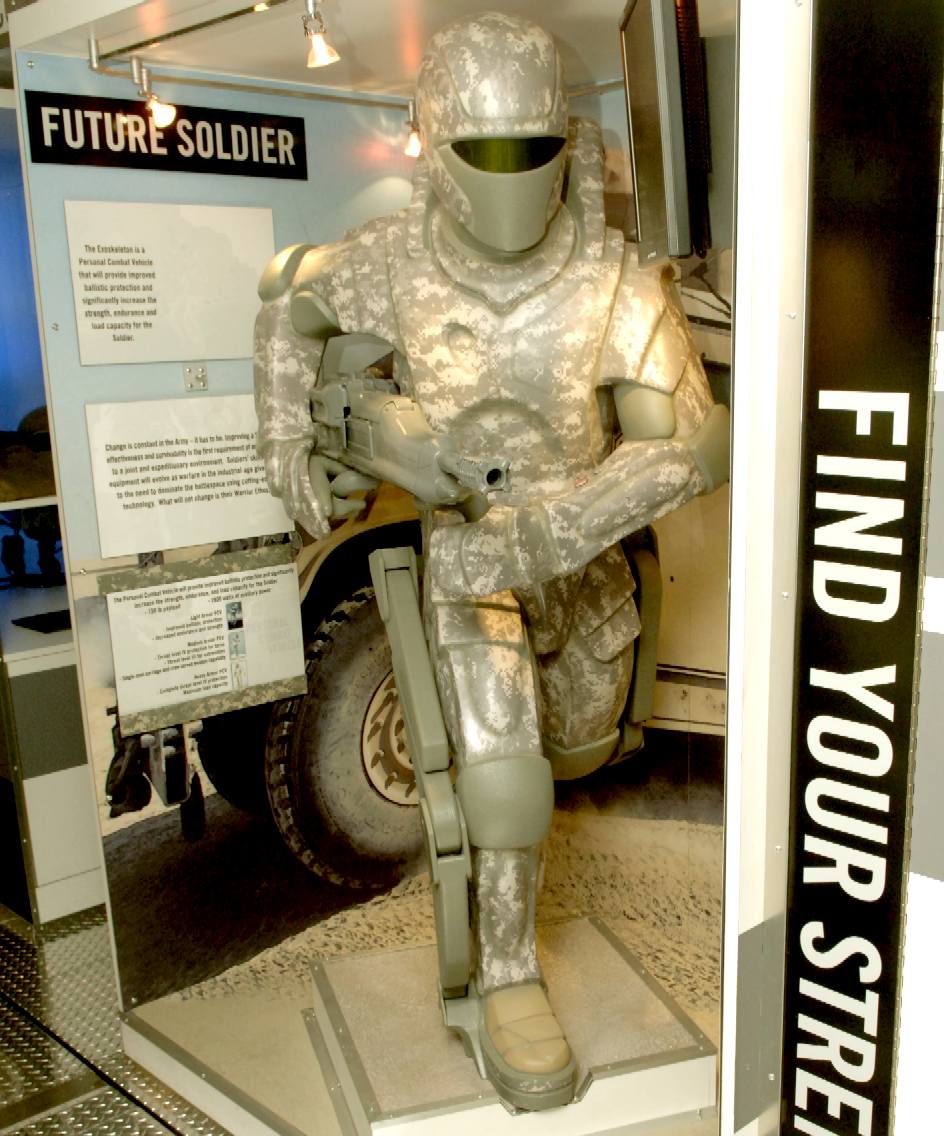

wars TV series. POWERED

EXOSKELETON A powered exoskeleton, also known as powered armor, exoframe, or exosuit, is a mobile machine consisting primarily of an outer framework (akin to an insect's exoskeleton) worn by a person, and powered by a system of motors, hydraulics or Pneumatics that delivers at least part of the energy for limb movement.

The main function of a powered exoskeleton is to assist the wearer by boosting their strength and endurance. They are commonly designed for military use, to help soldiers carry heavy loads both in and out of combat. In civilian areas, similar exoskeletons could be used to help firefighters and other rescue workers survive dangerous environments. The medical field is another prime area for exoskeleton technology, where it can be used for enhanced precision during surgery, or as an assist to allow nurses to move heavy patients.

Working prototypes of powered exoskeletons, including XOS by Sarcos, and HULC by Lockheed Martin (both meant for military use), have been constructed but have not yet been deployed in the field. Several companies have also created exosuits for medical use, including the HAL 5 by Cyberdyne Inc.

An electric powered leg exoskeleton developed at MIT reduces the metabolic energy used when walking and carrying a load. The exoskeleton augments human walking by providing mechanical power to the ankle joints.

Ekso Bionics is currently developing and manufacturing intelligently powered exoskeleton bionic devices that can be strapped on as wearable robots to enhance the strength, mobility, and endurance of soldiers and paraplegics.

Various problems remain to be solved, the most daunting being the creation of a compact power supply powerful enough to allow an exoskeleton to operate for extended periods without being plugged into external power.

BULLET

PROOFING Bulletproofing is the process of making something capable of stopping a bullet or similar high velocity projectiles e.g. shrapnel. The term bullet resistance is often preferred because few, if any, practical materials provide complete protection against all types of bullets, or multiple hits in the same location.

Dr George E Goodfellow (Tombstone, Arizona) wrote an article for the Southern California Practitioner titled "Notes on the Impenetrability of Silk to Bullets". He experimented with designs for bullet-resistant clothing made of multiple layers of silk. His article was based on observations as to real gunshot attacks where silk had prevented penetration. By 1900, gangsters were wearing $800 silk vests to protect themselves. ABOUT BULLETS

Bullet designs vary widely, not only according to the particular firearm used (e.g. a 9×19mm Parabellum caliber hollowpoint handgun cartridge will have inferior penetration power compared to a 7.62×39mm rifle cartridge), but also within individual cartridge designs. As a result, whilst so-called "bullet-proof" panels may successfully prevent penetration by standard 7.62×39mm bullets containing lead cores, the same panels may easily be defeated by 7.62×39mm armor piercing bullets containing hardened steel penetrators.

Bullet-resistant materials (also called ballistic materials or, equivalently, anti-ballistic materials) are usually rigid, but may be supple. They may be complex, such as

Kevlar, Lexan, and

carbon fiber composite materials, or they may be basic and simple, such as steel or titanium. Bullet resistant materials are often used in law enforcement and military applications, to protect personnel from death or serious

injuries CLASSIFICATION

There are various mandatory tests which items must pass before they can be classified as bullet-resistant. These tests specify the detailed characteristics of bullets which the material or object must be resistant to. For example, the United States National Institute of Justice standard 0104.04 for bullet-resistant vests specifies that a Type II vest must not deform clay representing the wearer's body when hit by an 8.0 g (124 gr) 9 mm caliber round nosed full-metal jacket bullet travelling at up to 358 m/s (1175 ft/s); but a Type IIIA vest is needed for protection against the same bullet travelling at up to 427 m/s (1400 ft/s). In both cases, the vest is not required to protect against a second hit within 51 mm (2 inches) of the first.

DAILY

MAIL AUG 2014 - Security-conscious drivers can put their worries at ease after BMW unveiled its latest armoured car with claims it can withstand the fire from an AK-47.

The German manufacturer revealed the BMW X5 Security Plus car at the Moscow Motorshow, which is taking place in the Russian capital this week.

Many of the world's top car makers chose to display their bullet-proof cars at the event, with BMW claiming it is the first manufacturer to offer protection from an AK-47 attack.

According to BMW, the X5 Security Plus provides protection from all kinds of street crime, whether the vehicle is attacked by a blunt object or by a handgun.

And they add: 'Officially certified as offering class VR6 ballistic protection, it is the first vehicle specifically designed to protect against the world’s most widely used firearm, the AK-47, while at the same time offering drivers the everyday flexibility they need.'

The car is fitted with special steel and shatterproof glass and comes with an eight-cylinder, turbocharged engine generating 450 horsepower, which means drivers can power their vehicle away if they feel they are in danger.

Other safety features customers can chose from include run-flat tyres, a self-sealing fuel tank, an attack alarm and an intercom system.

But despite the safety features, BMW also add that it drives like any other sports utility vehicle offered by the company.

However, with normal X5 series vehicles starting from £43,000, an X5 Security Plus is likely to cost around £110,000.

The model joins BMW's previous security car, the BMW 7 Series High Security, which is designed for high-ranking officials and corporate executives.

When he was Prime Minister, the possible war criminal, Tony Blair (he needed it) took delivery of a fully armoured BMW 7-series — dubbed the ‘Blair Panzer’ after the German word for armour.

David Cameron has, as his official car, an armoured, top-of-the-range Jaguar XJ.

But trumping them all is U.S. President Barack Obama with his gargantuan armoured Cadillac-style limousine, dubbed ‘The Beast’, which follows him around the globe on official visits.

Demand for armoured cars is on the increase in the U.S. while in Britain they are popular with Eastern European oligarchs.

Luxury car-makers such as Jaguar Land Rover, BMW, Bentley and Mercedes-Benz already have their own ‘in-house’ security arms which build in armouring from scratch.

PROTECTION

ON THE STREETS

- This is a typical bullet proof vest, but not the kind of protection that

a robot needs.

BULLET

PROOF VESTS Vests designed for bullets offer little protection against blows from sharp implements, such as knives, arrows or ice picks, or from bullets manufactured of non-deformable materials, e.g., those containing a steel core instead of lead. This is because the impact force of these objects stays concentrated in a relatively small area, allowing them to puncture the fiber layers of most bullet-resistant fabrics. By contrast, stab vests provide better protection against sharp implements, but are generally less effective against bullets.

Textile vests may be augmented with metal (steel or titanium), ceramic or polyethylene plates that provide extra protection to vital areas. These hard armor plates have proven effective against all handgun bullets and a range of rifles. These upgraded ballistic vests have become standard in military use, as soft body armor vests are ineffective against military rifle rounds. Prison guards and police often wear vests which are designed specifically against bladed weapons and sharp objects. These vests may incorporate coated and laminated para-aramid textiles or metallic components.

ARMOUR PIERCING AMMUNITION

The standards for armor-piercing rifle bullets aren't clear-cut, because the penetration of a bullet depends on the hardness of the target armor. However, there are a few general rules. For example, bullets with a soft lead-core and copper jacket are too easily deformed to penetrate hard materials, whereas rifle bullets manufactured with very hard core materials, like tungsten carbide, are designed for maximum penetration into hard armor.[48] Most other core materials would have effects between lead and tungsten carbide. Many common bullets, such as the 7.62×39mm M43 standard cartridge for the AK-47 rifle, have a steel core with hardness rating ranging from Rc35 mild steel up to Rc45 medium hard steel.

Additionally, as the hardness of the bullet core increases, so must the amount of ceramic plating used to stop penetration. Like in soft ballistics, a minimum ceramic material hardness of the bullet core is required to damage their respective hard core materials, however in armor-piercing rounds the bullet core is eroded rather than deformed.

The US Department of Defense uses two classes of protection from armor-piercing rifle bullets. The first, the Small Arms Protective Insert (SAPI), called for ceramic composite plates with a mass of 20–30 kg/m2 (4–5 lb/ft2). Later, the Enhanced SAPI (ESAPI) specification was developed to protect from more penetrative ammunition. ESAPI ceramic plates have a density of 35–45 kg/m2 (7–9 lb/ft2), and are designed to stop bullets like the 7.62 x 63 AP(M2) with an engineered hard core.

Cercom, now BAE systems, CoorsTek, Ceradyne, Tencate, Honeywell, DSM, Pinnacle Armor and a number of other engineering companies develop and manufacture the materials for composite ceramic rifle armor.

BOMB BLASTS

Armor designed primarily to counter explosives is often somewhat less effective against bullets than armor designed for that purpose. The sheer mass of most bomb disposal armor usually provides some protection, and bullet-specific trauma plates are compatible with some bomb disposal suits. Bomb disposal technicians try to accomplish their task if possible using remote methods (e.g., robots, line and pulleys). Actually laying hands on a bomb is only done in an extremely life-threatening situation, where the hazards to people and critical structures cannot be lessened by using wheeled robots or other techniques. CERAMICS

Ceramic materials, materials processing and progress in ceramic penetration mechanics are significant areas of academic and industrial activity. This combined field of ceramics armor research is broad and is perhaps summarized best by The American Ceramics Society. ACerS has run an annual armor conference for a number of years and compiled a proceedings

2004–2007. An area of special activity pertaining to vests is the emerging use of small ceramic components. Large torso sized ceramic plates are complex to manufacture and are subject to cracking in use. Monolithic plates also have limited multi hit capacity as a result of their large impact fracture zone These are the motivations for new types of armor plate. These new designs use two- and three-dimensional arrays of ceramic elements that can be rigid, flexible or semi-flexible. Dragon Skin body armor is one of these systems. European developments in spherical and hexagonal arrays have resulted in products that have some flex and multi hit

performance. The manufacture of array type systems with flex, consistent ballistic performance at edges of ceramic elements is an active area of research. In addition advanced ceramic processing techniques arrays require adhesive assembly methods. One novel approach is use of hook and loop fasteners to assemble the ceramic arrays.

DRAGON SKIN ARMOUR

Dragon Skin is a type of ballistic vest formerly made by the now defunct company Pinnacle Armor. It was invented and developed by American Murray Neal and is currently produced in Missoula, Montana by North American Development Group LLC available for public, law-enforcement and military customers. Its characteristic two-inch-wide circular discs overlap like scale armor, creating a flexible vest that allows a good range of motion and is intended to absorb a high number of hits compared with other military body armor. The discs are composed of silicon carbide ceramic matrices and laminates, much like the larger ceramic plates in other types of bullet resistant vests.

The armor is currently available in one basic protection level: Dragon Skin Extreme (formerly SOV-2000), which has previously had certification to Level III protection;

Dragon Skin has been worn by some civilian contractors in Iraq, some special operations forces in Iraq and

Afghanistan, some SWAT teams, nine generals in Afghanistan, bodyguards tasked with protecting generals, and U.S. Secret Service personnel. The Central Intelligence Agency (CIA) has also purchased Dragon Skin.

In Fresno, California, a police department commissioned the purchase of Dragon Skin for its officers after a vest stopped all the bullets fired during a test, including .308 rounds from a rifle and 30 rounds from a 9mm MP5 fired from five feet away. Ninety-eight federal, state, and local law enforcement officers witnessed the SWAT test. The armor also stopped 40 rounds of PS-M1943 mild

steel-core bullets from an AK-47 along with 200 9 mm full metal jacket bullet fired from a submachine gun. ACADEMIC

DRAGON SKIN TESTS Dragon Skin Level III armor was also tested the week of October 2, 2006 by Dr. Gary Roberts, DDS, Stanford University Medical Center. These tests were conducted for a local law enforcement agency, as a control sample a stand-alone Armored Mobility Incorporated (AMI) level III steel composite plate armor was used for comparison. Both types of armor were conditioned for 12 hours at 170 °F (77 °C), then moved to ambient air for approximately 90 minutes prior to being shot. The problems associated with the use of inelastic clay backing material have been well documented; as such, the armor was secured to a life-size curvilinear torso replica made of Perma-Gel. Each armor system was shot a minimum of 20 times with five rounds of each ammunition type fired against each armor system—one 90 degree perpendicular shot, two shots at 60 degrees obliquity, and two shots at 30 degrees obliquity, using each of the following loads fired at a distance of 10 feet (3.0 m):

* 5.56 mm 40 gr LeMas Urban Warfare (using a moly coated Nosler Ballistic Tip bullet) with a 3,718 feet (1,133 m) per second average velocity.

*

5.56 mm M855 62 gr FMJ with a 3,054 feet (931 m) per second average velocity.

*

7.62×39mm M43 123 gr steel-core FMJ with a 2,307 feet (703 m) per second average velocity.

*

.30-06 M2 150 gr FMJ with a 2,736 feet (834 m) per second average velocity.

All of the above ammo was successfully stopped by both armor systems in this testing, with no armor failures or penetrations, even after receiving multiple hits.

LEFT

- Movie idea, lurking beneath the Antarctic

ice is a discovery that scientists will die for. This story is now the subject

of a low budget trailer to be produced mostly in the UK. The promoters are

looking for backers. The UK will contribute 20% toward production costs.

Roughly 60% of a low budget film may be pre-sold as distribution rights,

leaving 20% finance to source. The deal is that investors recover 120% on their

project stake within 12 months of shooting, with

an income stream thereafter from networks and merchandising. Look at what happened when they remade Godzilla.

ENGINEERING

DESIGN

- Ants are fabulous fighting machines. Biological engineering is less of a

compromise than man-made machines. The only advantage that man-made machines have have

is that we can use any material we want to seek to compensate

for design and manufacturing limitations.

A

Sectasaur™ (thawed) - now on permanent display at Herstmonceux

Museum, in Sussex, England.

ANTICS

- ARDUINO

- ARMOUR

- ARTWORK

- BIPEDAL

HUMANOIDS - BLACK

BOX -

CHAT GPT

- ELECTRONICS - ENERGY - FRAME

- FORMICARIUM

HEAD -

INVISIBILITY

- JAWS -

KITS -

LEGS - MECHANICS

- MOTORS -

MOVIE

- RASPBERRY

Pi - R/C DRONE - SENTRY

- SOFTWARE

SIM

CARDS - SMARTPOHNES

- SOUND PROOFING

- SPACE

ROVERS - SPEED

- STEM

- SUSPENSION

- TAIL

- WEAPONS

- WARGAMING

|