|

THE MAGICAL DINOBOT - CHAPTER TWELVE

|

||||||||||||||||||||||||||||||||||||||||||

|

JIMMY

WATSON

-

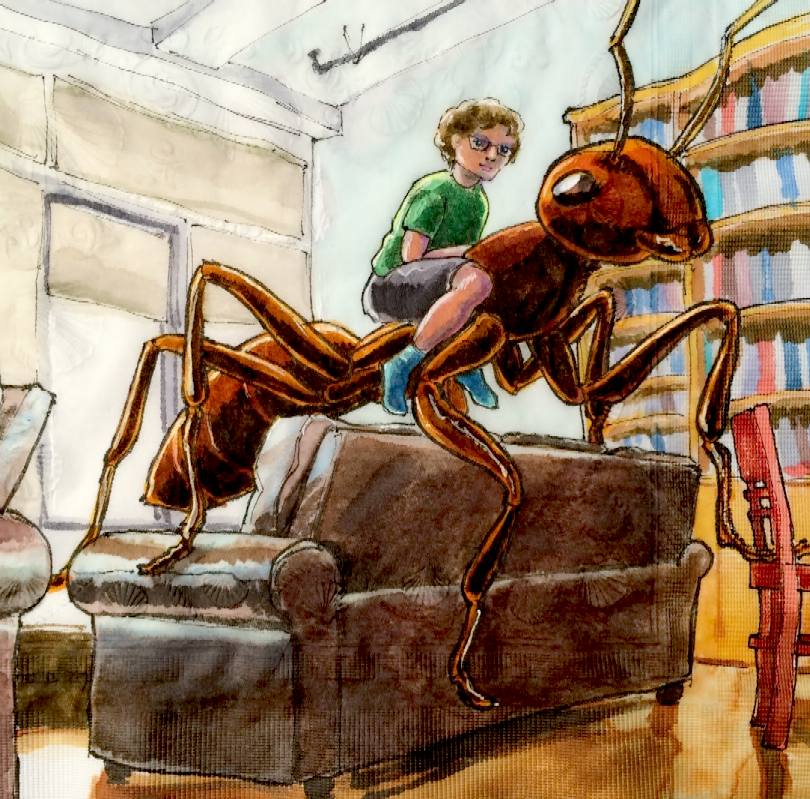

His mother, Marion, teases her son about his dreams to build a large robot ant with a

drawing of her son riding on the ant's back. Then it comes true.

第12章 - 電気配線の課題

ジミーは進歩に満足していた。モーターは一時的な直流電源を取り付けてテストされたが、非常に大きな火花を伴う頑丈なワニ口留め金を外す以外は、巧妙さや制御は一切なかった。そしてそれは非常に危険な実験であることが判明した。ダイノボットはサイクルアセンブリマウントから落ちそうになり、激しいフルパワートルクから再びオフになり、さらに火花が飛ぶたびに、どんなダメージを与えるか誰にもわからない。

...

Jimmy was pleased with progress. The motors were fitted and tested by rigging a temporary DC supply, with no finesse or control, other than unclamping a heavy duty crocodile clasp, accompanied by very large sparks. And that proved to be quite a risky experiment, where the dinobot almost fell off the cycle assembly mounts, to do who knows what damage with each jolt from violent full power torque, to off again, and more sparks.

Jimmy vowed not to try that again. His heart could not stand those kind of frights. He was shaking all over when that happened, and perspiring. He needed to have a wash and change his T shirt after that little episode. Liberally applying antiperspirant after showering in his bedroom. Then back downstairs to the workshop.

His father, Tim, had been most helpful in arranging reels of colour coded wires of different capacities along one wall, conveniently below other tools: engineers pliers, side cutters, wire strippers. Jimmy loved the way his Dad was so logical and matter of fact. It filled him with confidence and admiration.

Jimmy thought about the time and motion study he'd undertaken at school in his statistics class. What seemed useless number crunching, might now be useful. Especially when combined with his ergonomics fascination. The art of matching humans to controls or, in this case, a work station. The layout and precise positioning of robot in the workshop, would determine how quickly and efficiently he could complete a fairly complex wiring task. Where some of the spade connections needed to be soldered, then protected by heat shrink tubing. For insulation, strength and ordered appearance. That might help fault finding further down the line. Debugging. He hated fault finding, but sometimes things went wrong.

Jimmy tightened up the clamps on the two 500w speed controllers. That was satisfying, final alignment. These two aluminium finned boxes were packed with power electronics, to provide infinitely proportional control of power fed to the main drive motors. It meant smooth control of the walking functions: forward, left and right and reverse, left and right - would be possible.

Jimmy built in a number of safeguards. A manual switch to power up the whole shebang. And a wireless switch that also turned on the power from the batteries to the wiring loom, upstream of the manual cut out.

Long ago Jimmy learned the hard way, that the trick with wiring was to first of all draw out a circuit diagram. That way he could think through the logical position of wires and electrical parts, before actually cutting the copper cables. Mistakes were virtually eliminated, this way. And there was always hard reference, with colour coding, that other engineers could understand. Jimmy also used a Dymo Rhino label printer that his Dad had bought for him when they were on special offer from Radio Spares. This was useful where many cables were the same colour, but could be number coded with information labels stuck to the chassis or components.

Soldering was another skill Jimmy had picked up during 'Robot Wars' challenges at school. He bought a number of electric irons. Some small with fine copper tips for working on circuit boards, and others with serious wattage grunt, for thick cables to motors. Crimping was fine for most applications where the copper wire was clean and brand new, a system used in cars and trucks. But with robots that had to work in all weathers. Sometimes it had to be a soldered joint to remain resistance free. The same applied in the nautical world. Even in model boats and 4x4 buggy racing, speed controllers needed to be waterproof.

Having produced a number of circuit diagrams, finally, Jimmy had one that was neat enough to be readable. Including all the components, colours for wires and notes to remind him of any pitfalls.

Dai 12-shō - denki haisen no kadai

..

ANTICS - ARDUINO - ARMOUR - ARTWORK - BLACK BOX - ELECTRONICS - ENERGY - FRAME - FORMICARIUM HEAD - JAWS - KITS - LEGS - MECHANICS - MOTORS - MOVIE - RASPBERRY Pi - R/C DRONE - SENTRY SOFTWARE - SOUND PROOFING - SPACE ROVERS - SPEED - SUSPENSION - TAIL - WEAPONS - WARGAMING

|

||||||||||||||||||||||||||||||||||||||||||

|

BEGIN AGAIN OR READ JIMMY'S PROJECT DIARY

This website is Copyright © 2024 Jameson Hunter Limited. Planet Earth.

|