|

THE MAGICAL DINOBOT - CHAPTER ELEVEN

|

||||||||||||||||||||||||||||||||||||||||||

|

JIMMY

WATSON

-

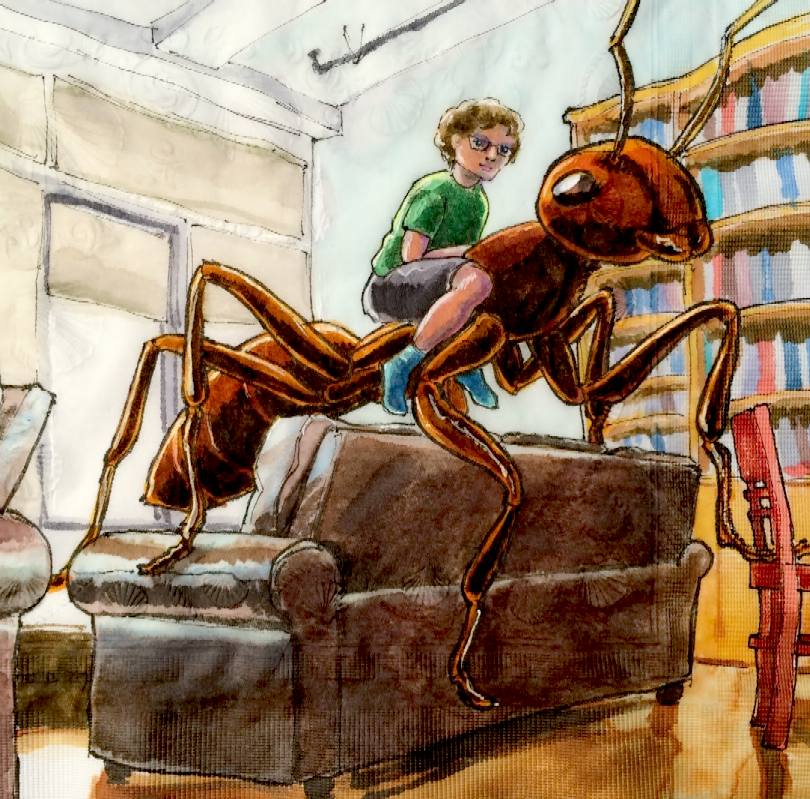

His mother, Marion, teases her son about his dreams to build a large robot ant with a

drawing of her son riding on the ant's back. Then it comes true.

CHAPTER 11 - JIMMY FITS THE DRIVE MOTORS

第11章 - ジミーが駆動モーターを取り付ける

2

つの自転車組み立てフレームで下から支えられ、六脚が形になりつつありました。脚はすべて取り付けられていましたが、地面と接触して正しい歩行パターンを常に保てるように互いに接続されていませんでした。モーターとドライブ チェーンを設置して脚を所定の位置に固定しない限り、この問題は解決できませんでした。

アンソニーも、同様に難題でした。もちろん、完成すれば、誰もその開発に二の足を踏むことはありません。

彼が注文したモーターは、ブラシレス

DC ユニットの場合よりも少し重かったが、予算が限られていた。彼が選んだのはブラシ付きで、ペダル バイクを電動ドライブに変換するために減速ギアボックスが付属していた。ジミーは適切な取り付けブラケットを作り、それを溶接した。次にモーターをボルトで固定した。次に電子スピード コントローラーをボルトで固定した。これらは、潤滑油が飛び散るチェーンやスプロケットから離れた場所に置いた。

...

Supported from underneath by two pushbike assembly frames, the hexapod was taking shape. All the legs were fitted, but were not connected to one another to have the correct walking pattern in contact with the ground at any one time. This problem could not be overcome, without installing the motors and drive chains, to lock the legs in position.

Jimmy thought of the complications of valve timing on an ordinary internal combustion engine. A virtual symphony of metal in machine harmony. And yet an everyday and seemingly mundane function that few drivers appreciated, on their way to do the shopping run. Whereas, Jimmy imagined all sixteen valves of his Mum's car dancing to the tune of her push on the accelerator pedal.

Twin motors and speed controllers for the Magic Dinobot

Anthony, was no less a challenge. Of course, once perfected, nobody would give the development a second thought.

The motors needed to be powerful enough to move the mass of the robot, and carry a decent load. Jimmy was working on transporting an average weight human rider. For which he'd need a saddle and voice control, or reins to give directional signals to his would be mechanical steed. If riding the machine like a horse. Jimmy didn't fancy bareback, like Ant Man, when catching a lift on flying ants.

He calculated that eight hundred watts with suitable gearing would probably suffice to begin with. The power would come from two four hundred watt motors. They would drive chains for each side of the robot's three chainwheels - one for each leg, to give variable track steering. Designing gears being too expensive and complicated for a prototype. In any event chains are very efficient. Around 95%, gears less so. But gears last longer with good transmission oils. And rubber belt drives like that used on camshafts in cars, even less efficient. And they snap.

The base frame was solid, allowing mountings for the motors to be added quite easily. Not in any way over stressing the structure. His designing was more based on hunches, and years of Lego and Meccano building. He knew instinctively if something would work. Just needing to work out the thickness of metal sections to use. The ability to weld completely changed his life. His whole outlook on what is and is not possible. No more nuts and bolts as the limiting factor. Welds gave a permanent fix in seconds. The downside being if you welded something in the wrong place. Then you'd need to cut the metal to remove and re-fit in the correct position. That happened a few times to begin with.

Anthony's steel chassis inverted showing the drive shafts and bearing blocks. Once Jimmy has bolted the chain sets onto these shafts, he can test drive motors.

One side completed of Anthony's chain set completed, bar the driving motor and chains. Jimmy is using 42 teeth per sprocket for the prototype. The bearings shown are for alignment purposes only. Leg cranks, or ends fit into spherical bearings in to give movement to the Dinobot's legs - all synchronized, to describe one of the walking cycle - or revolution of the left leg bank.

The motors he had ordered were a little heavier than they might be if they were brushless DC units, but he was on a budget. The ones he chose were brushed, with a reduction gearbox as supplied to convert pedal bikes to electric drives. Jimmy made suitable mounting brackets, which he welded in place. Then he bolted on the motors. Next he bolted on the electronic speed controllers. These he kept away from the chains and sprockets that splashed lubricating oil.

It was time to do a quick static test. Would the motors and controllers work from the inputs.

His mobile phone jangled. Jimmy checked out the message. It was Julia: "Can I come round and help."

"Oh please, but test wiring up the beast's primary drives. Could be boring and dangerous."

"See you in a few minutes."

Jimmy took a look long at the dinobot's frame, patted it, said "good boy Anthony," and went into the kitchen to grab a Solar Cola and greet Julia.

There was a ring on the front doorbell. Marion went to the door. "Hello Julia, dear. Jimmy is in the kitchen, help yourself to a soda pop, or would you like a nice cup of tea?"

"Thank you Mrs Watson, how are you and Mr Watson. I'll have a Solar Cola if that is okay?"

Julia went into the kitchen, greeted by a huge smile from Jimmy, who had her favourite cola waiting for her.

They both scampered into their new wooden retreat. Julia was amazed at the progress Jimmy had made in just the last couple of weeks.

Dai 11-shō - jimī ga kudō mōtā o toritsukeru

...

ANTICS - ARDUINO - ARMOUR - ARTWORK - BLACK BOX - ELECTRONICS - ENERGY - FRAME - FORMICARIUM HEAD - JAWS - KITS - LEGS - MECHANICS - MOTORS - MOVIE - RASPBERRY Pi - R/C DRONE - SENTRY SOFTWARE - SOUND PROOFING - SPACE ROVERS - SPEED - SUSPENSION - TAIL - WEAPONS - WARGAMING

|

||||||||||||||||||||||||||||||||||||||||||

|

BEGIN AGAIN OR READ JIMMY'S PROJECT DIARY

This website is Copyright © 2024 Jameson Hunter Limited. Planet Earth.

|